Project quality control

Quality Commitment

*The qualified rate of finished products ≥ 99.5%

*The first pass rate of manufacturing process ≥ 96%

*Customers complaint per month ≤ 1 time

Quality Assurance

Quality is vital to an enterprise, we persist in "focus on customers" as quality management concept and conscientiously implement the ISO 9001:2015 standard.

Strictly control for whole processing

*Engneering, quality, production department hold kick off meeting for totally understanding of all new projects details.

* Weeky report updated with pictures and videos per weeks with status sharing to make sure customer easy tracing. Engineer will take responsibility for monitor for correct manufacturing.

* Steel certification, heat-treatment report and QC report for materials.

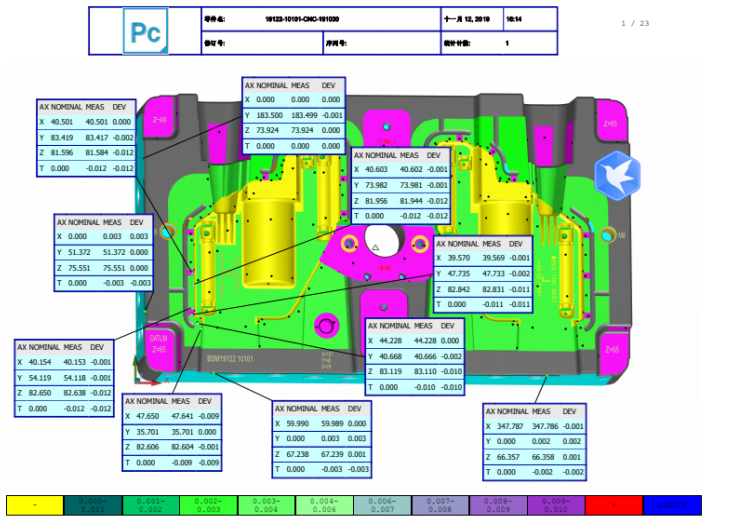

*CMM, projector, vernier caliper, hardness tester etc for inspection and Dimension FAI report, injection parameter,other testing report etc sent to customers before shipping.

* IQC, IPQC and OQC for full processing quality control.

Quality is always life enterprise, our goal is provide good quality with most cost-effective solutions.

TT Mould and Machining will keep quality priority. We believe quality lighting future.

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province