Reason

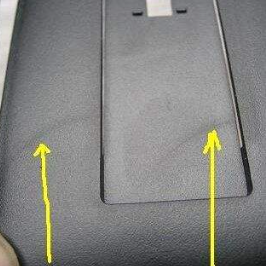

Injection Molded parts may encounter poor clamping during the inflow process, resulting in the formation of bonding lines, which can also occur during the flow process

Another situation where there is a similarity in the fusion line (Meld line). The main reasons for the two are roughly the same, whether it is the design of plastic parts or not

The most important reason for poor or inadequate injection Molding conditions is the temperature drop of=or>10 degrees generated during the peak of the converging flow.

Improvement methods:

a) Plastic

Replace with a higher flow level plastic materil

b) Mold

Avoid sudden changes in design thickness

Gates should not be set up in thin locations

Check if the exhaust duct is blocked

Add surface treatment to the Mold

Relocation at the entrance (the purpose will be to relocate along the line)

c) Injection Molding machine conditions

Increase the Mold temperature

Increase injection speed

Increase the temperature of the melt adhesive

Increase the holding pressure

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province