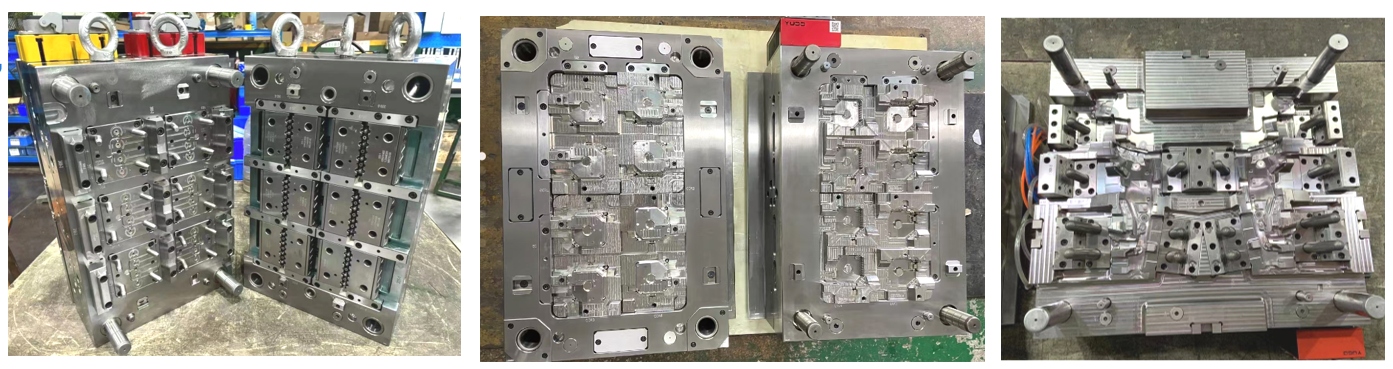

Automotive molds making

Mold for Audi interior parts

TTM Mold making experience and stardard.

★Mold type TTM can supported?

Prototype Molds, injection Mold, die casting Mold,stamping Mold,silicone Mold etc.

★ TTM Mold making for related industry?

Automotive industry, medical industry, household, Energy storage industry, Pets industry, Garden industry etc.

★TTM customers located?

USA, Europe (UK, Ireland,Germany,Denmark, Portugal etc ), Australia and UAE etc.

★ TTM Mold tolerance?

Accurate can be +/-0.03mm for plastic Molded parts. Mold Machining tolerance can be 0.005mm.

★ TTM mold base standard?

LKM, HASCO, DME equivalent and customized.

★ Plastic material used for molds?

ABS, PC, PC+ABS, PMMA, PP, HIPS, HDPE, PA12, PA6, PA66+GF,POM, PET, PBT, PBT+30%GF, TPE,TPU, PPSU,PEEK, POM etc,.

★Mold layout of TTM?

Single cavity injection mold, muti-cavity injection mold, family mold, over mold, 2K mold, thin wall mold, MUD mold etc.

★Injection System?

Cold runner, hot runner, gas-assisted injection etc.

★ Core and cavity mold steel used in TTM?

1.2344, S136,H13,S7, NAK80,SS420, P20,1.2312,1.1730, 1.2738, 738H and other steel according to customer mould requirement.

★Type of gating?

Side gate, Sub gate, Pin point gate, Edge gate, Reversed gate etc

★Surface finish?

VDI, Mold-Tech, YS Texture, EDM, Polishing with SPI standard, etc

★Ejection types of TTM?

Ejector pins, ejection block, stripper plate, gas-cap driving etc

★Mold release solution of TTM?

Sliders, lifters, Hydraulic cylinder, gear etc.

★Hot runner brand used?

Mold Masters, Yudo, Synventive, Incoe, etc.

★ Mold size of TTM can supported?

Middle sized mold with big strength in TTM, biggest mold can be 1.5 meter with 12 Ton.

★ Lead time of TTM mold making?

3~8 week based on mold structures from mold design approval to T1. 98% mold approved for shipping within T3.

★ Lead time of TTM mold design.

Quotation within 24 hours.

DFM/Mold flow: 2~3 working days, 2D design: 2~4 working days, 3D design: 3~5 working days.

TTM Mold making processing.

Step 1 Product to production possibility evaluation.

DFM and mold flow etc (During this stage, TTM will suggest for design change for mold release to support parts move into production smoothly.

Step 2 Mold Design.

Mould drawing design, the 2D & 3D mould design should be confirmed by customers.

Step 3 Mold Machining and assembly.

After mould design is confirmed, we will order steel for components,mould base and mold cavity&core steel.And then start steel Machining etc.

Mold weekly report will send to customer every Monday to make sure customers have all things schedules.

Step 4 Mold trial and samples shipping

After mold fitting, we’ll arrange mold trial out. and send customer mold trial report with mold pictures, samples photo, short shots and molded parts issues and our solutions. And send samples out after approval.

In ther meanwhile, parts inspection report, mold injection parameter, Molding trial video will be provided after mold trial.

Step 5 Mold correction and modification.

According to samples assembly, we’ll make corrcections or modifications based on customers request as fast as we can.

Step 6 Mold approval and mold shipping.

Mold will shipped after customer samples approval.

Normally vacuum packing, anti-rust paper, film etc based on shipping method of by sea, by air or by train.

Mold shipping preparation including mold clean up, mold checking according to checking list, molds documents.

Mold BOM, mold 2D/3D drawings, material certifications, spare parts, heat treatment certification, photos and mold shipping report etc document will send to customer via email.

Paper work with USB momory card to together to put into shipping box.

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province