Soft 3D printing

Customized for hardness.

1PCS MOQ, lead time can 3~5 days.

Customized design

0.05mm size accurate.

Size can be 800mm.

Various material for selection.

TTM can support high accurate to 0.05mm with various material for complex structure, the biggest size we can support is 800mm.

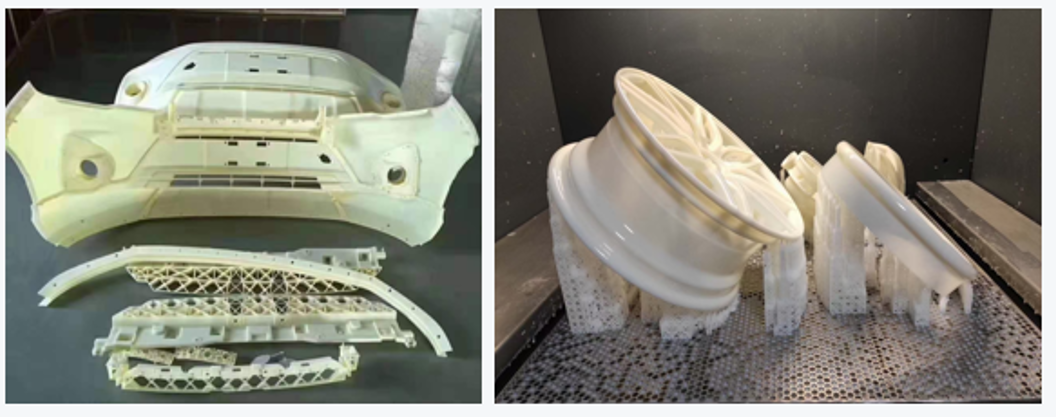

We can use SLS, SLM, SLA, FDM etc process for 3D printing parts.

Why use 3D additive printing?

3D printing normally use for product developing stage for low quanity or high special customized reuqest plastic parts.

3D printing advantages as below

• Shorter lead time (2~5 days)

• Customized precision and highly resilient components

• Good dimensional stability of components

• High quality control for vacuum cast parts

• Low shrinkage and excellent turning yellowing resistance

• Customized for special structure that CNC Machining or Molding can achieve.

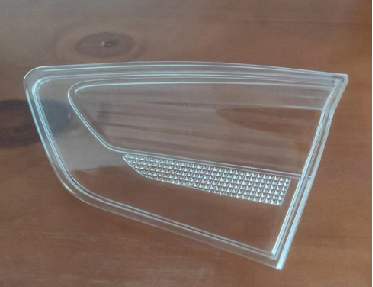

• Can print white, green, transparent, brown, red wax and other appearance

• A variety of different hardness options

• Thermal deformation temperature up to 80℃

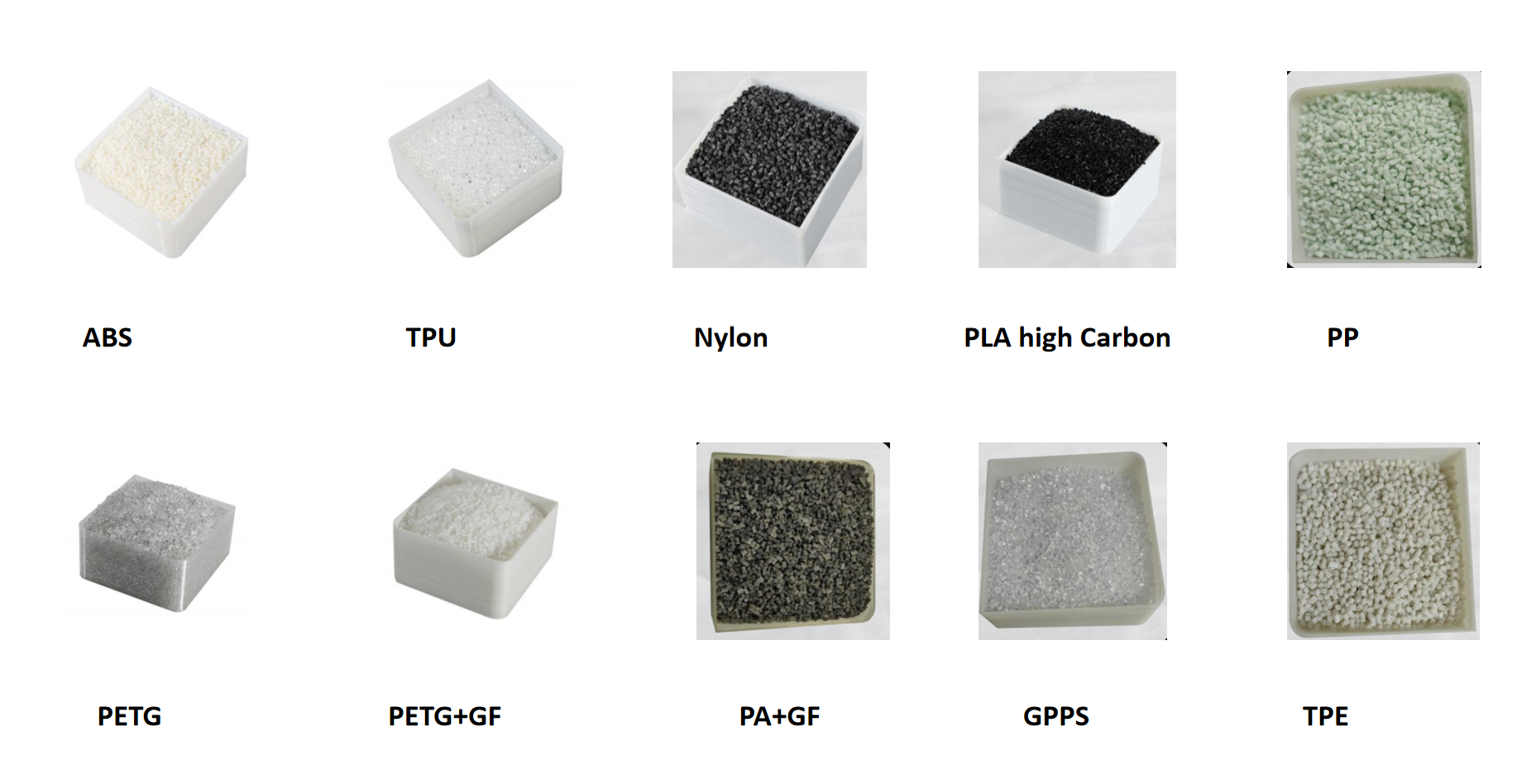

3D printing material and application.

Engineering plastic for industry of automotive, household, medical, aerospace,medical etc.

Photosensitive resin similar of ABS for industry of automotive, household and consumer electronics etc

Rubber material for industry of consumer electronics, medical, automotive interior parts etc.

Metal material for indsutry of aerospace, structure parts etc.

3D printing material

3D printing parts also can make surface treatment like printing, painting etc.

More contact TTM teachincal team.

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province