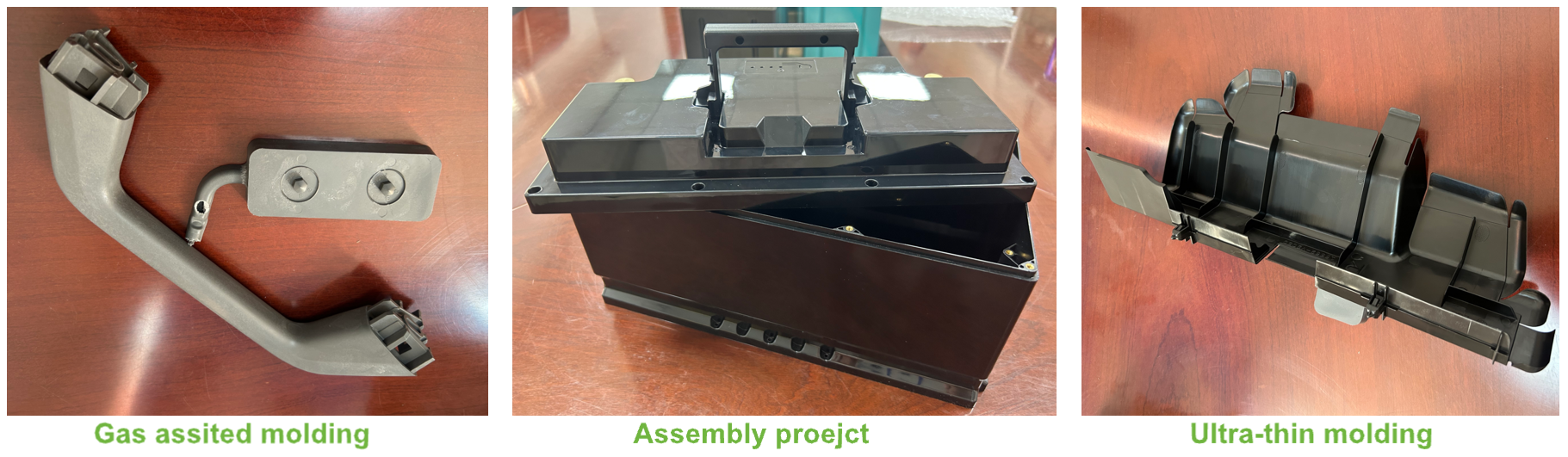

Automotive Battery box

3 injection molded parts

Insert molding with ultrasonic welding

1000 PCS annual usage

Soft steel to reduce cost.

Injection Molding is a widely used manufacturing process for producing plastic parts.

Here are some of its key advantages:

1. High Efficiency

Mass Production: Injection Molding is ideal for high-volume production due to its fast cycle times.

Automation: The process can be highly automated, reducing labor costs and increasing consistency.

2. Precision and Consistency

Complex Geometries: It allows for the production of complex and intricate shapes with high precision.

Consistency: Each part produced is virtually identical, ensuring consistent quality.

3. Material Versatility

Wide Range of Materials: A variety of thermoplastic materials can be used, including polyethylene, polypropylene, ABS, nylon, and more.

Material Properties: Different materials can be chosen based on the required properties such as strength, flexibility, and heat resistance.

4. Strength and Durability

Strong Parts: Injection-Molded parts are generally strong and durable, especially when reinforced with fibers or fillers.

Integrated Components: Multiple parts can be Molded together, reducing the need for assembly and increasing structural integrity.

5. Cost-Effectiveness

Low Per-Unit Cost: High initial tooling costs are offset by low per-unit costs in large production runs.

Reduced Waste: Excess material can often be recycled and reused, minimizing waste.

6. Surface Finish

High-Quality Finish: Parts can be produced with smooth surfaces and fine details, reducing the need for post-processing.

Customization: Various textures and finishes can be achieved directly in the Mold.

7. Scalability

Flexible Production: The process can be scaled up or down depending on demand, making it suitable for both large and small production runs.

Rapid Prototyping: With advancements in technology, injection Molding can also be used for rapid Prototyping.

8. Design Flexibility

Innovative Designs: Designers have the freedom to create innovative and complex shapes that might be difficult or impossible with other manufacturing methods.

Integration of Features: Features such as threads, undercuts, and inserts can be Molded directly into the part.

9. Reduced Assembly

Multi-Part Integration: Multiple components can be integrated into a single Molded part, reducing the need for assembly and associated costs.

Snap-Fits and Living Hinges: Design features like snap-fits and living hinges can be incorporated, simplifying assembly.

10. Environmental Considerations

Recyclability: Many thermoplastics used in injection Molding are recyclable, contributing to sustainability efforts.

Energy Efficiency: Modern injection Molding machines are designed to be energy-efficient, reducing the overall environmental impact.

In Summary Injection Molding offers numerous advantages, including high efficiency, precision, material versatility, cost-effectiveness, and design flexibility.

These benefits make it a preferred choice for manufacturing a wide range of plastic parts across various industries.

Plastic material for customized injection Molding?

ABS,PC, PC+ABS, PP, HIPS, HDPE, PA12, PA6, PA66+GF,POM, PET, PBT, PBT+30%GF, TPE,TPU, PPSU,PEEK,

POM,Acetal, PVC, Delrin, HDPE, LDPE, Nylon, PEEK, PET, PMMA(Acrylic), Polycarbonate, Polypropylene, Polystyrene etc

Molding processing?

Insert Molding, over Molding, 2K Molding, single cavity Molding, multi-cavity Molding, family injection Molding, ultra-thin Molding, air-assitant molding etc

Surface treatment?

UV&Soft&Rubber Painting, Plating, Pad printing, laser etching, fabric wrapping etc.

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province