Customized plastic metal parts

1pcs MOQ

Tolerance to 0.005mm.

CMM for inspection.

Material certification.

Advantages of CNC Machining

The process of CNC Machining provides multiple benefits for both Prototyping and production parts.

Precision and repeatability

Tight tolerances

Production-grade materials

Quick-turn parts within 1~3 working days

Lower piece-part price at higher quantities

Robust post-processing to improve cosmetics and material properties

CNC Machining Applications

CNC Machining is widely used throughout the aerospace, medical, automotive industries for its ability to rapidly Manufacture precise parts in production-grade materials.

Typical CNC parts, include:Housings and enclosures,Brackets,Fixtures for manufacturing,Gears and bearings,

Internal mechanical components,Medical instrumentation etc.

Automotive

Engine parts,suspension parts, transmission parts,Fuel system components etc

Oil&Gas

pumps,hydraulic equipment, subsea equipment, drilling rig components, pressure vessels etc

Medical equipment

Surgical instruments,medical device components, electronic components, medical fasteners, customized medical devices etc.

Aerospace

Aircraft engine parts, landing gear, fuel systems, control surface parts, interiors, fasteners, instruments, electronic equipment, and other precision parts that require fine Machining.

Construction

loader parts, crane parts, bulldozer parts, mixer parts, paving equipment, forklift parts, safety equipment parts, and other precision parts that require finishing.

Electronic Devices

Precision components such as housings, heat sinks, terminals, control unit frames, etc. in the fields of electronic components, electronics, consumer electronics, and automotive electronics.

Industrial Machinery

Automation machine parts, shafts, bearings, bushings, mounting plates, brackets, pulleys, hydraulic parts, pneumatic parts, chassis, cutting tools, control panels, and other precision parts that require etc.

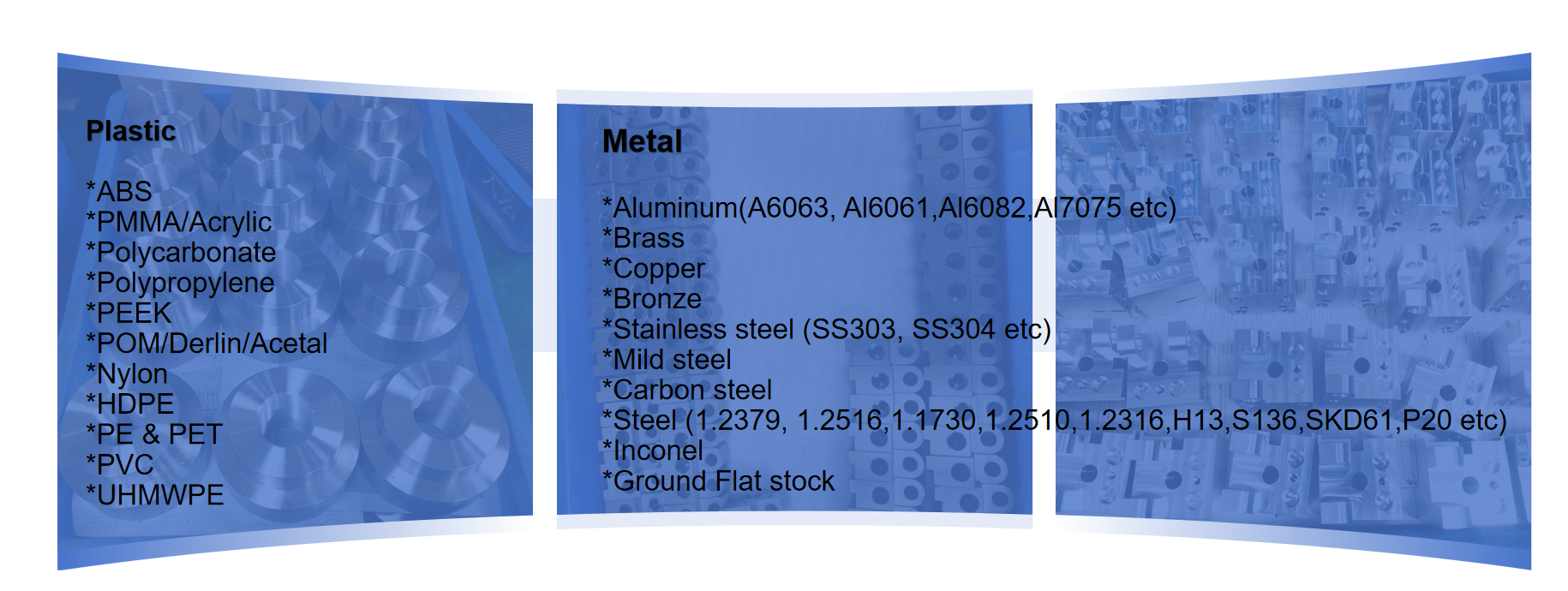

Machining material TTM used?

Plastics offer a versatile, cost-efficient solution for CNC Machining, balancing light weight design, corrosion resistance, and ease of production.Their adaptability makes them indispensable across industries, from Prototyping to high-performance engineering.

Aluminum is a popular choice for Machining becauso of its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion.

Brass is an alloying consisting of both copper and zinc. The gold materials is a weather- and corrosion- resistant metal with tensile strength similar to mild steel. It's also an easy to machine material, so feedrates can remain high and coolant need is minimal.

Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile.

Surface treatment TTM can support?

★ Edges/Sharp broken with tool marks visible

★ Anodizing (Clear anodizing, hard anodizing, black anodizing)

★ Chrome plating

★ Powder coating

★ Laser engraving

★ Brushing

★ Painting

★ Printing

★ Black Oxide etc

Tolerance TTM can reach?

Best can be 0.005mm for steel parts, plastic parts based on material, normally can be 0.05mm.

TT Mould and Machining Co.,Ltd

Contact:lucky

Mobile:86-13714904828

Email:info@ttmoulds.com

Add:Xiangfa tech Park, Loucun Community, Xinhu Street, Guangming District, Shenzhen City, Guangdong Province