———————————— Your reliable professional Mould and plastic metal products manufacturer ————————————

———————————— Enabling innovation through our Mould and Efficiency services. ————————————

———————————— Based on advanced technology and experienced stuff. ————————————

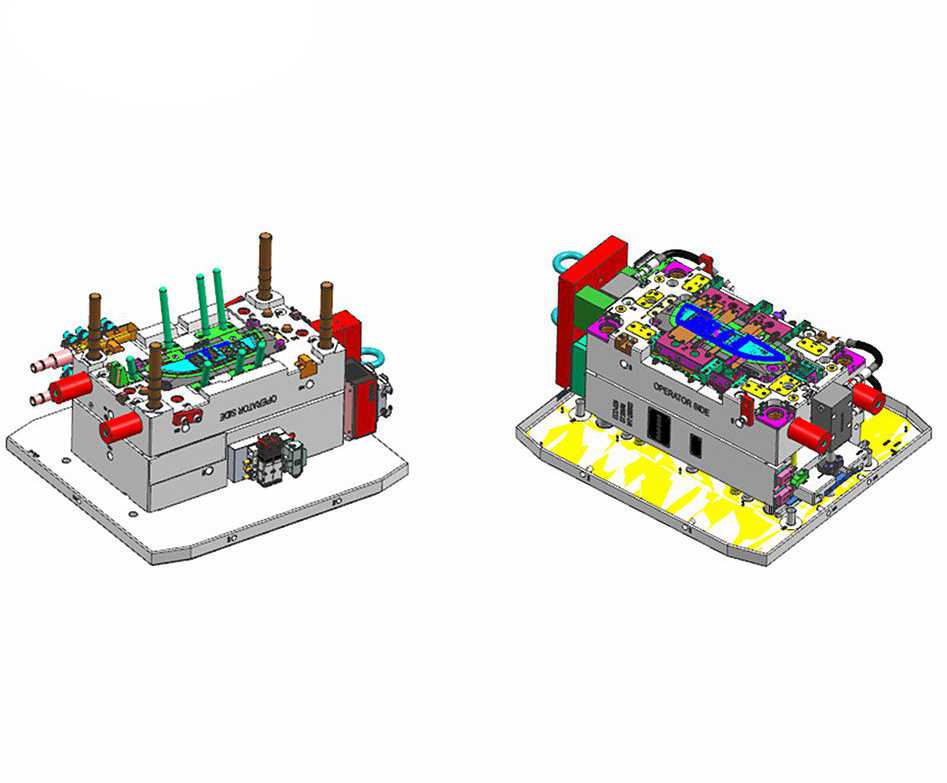

Mold DFM (Design for manufacturing analyse)

In DFM stage, we'll check injection gate, mold parting line, sliders, lifters, undercuts, sink markt etc to check mold production possibility and suggestion for parts change.

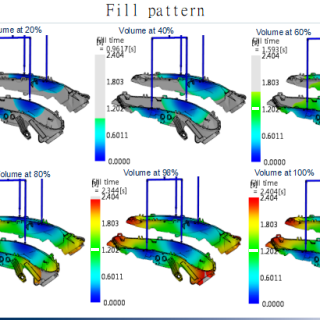

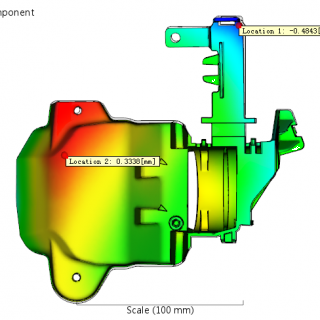

Mold Flow to simulatioing the mold filling, cooling, balance, cycle times etc.

Mold design (3D, 2D), confirm mold standard like DME, Hasco, or China standard mold leave in China

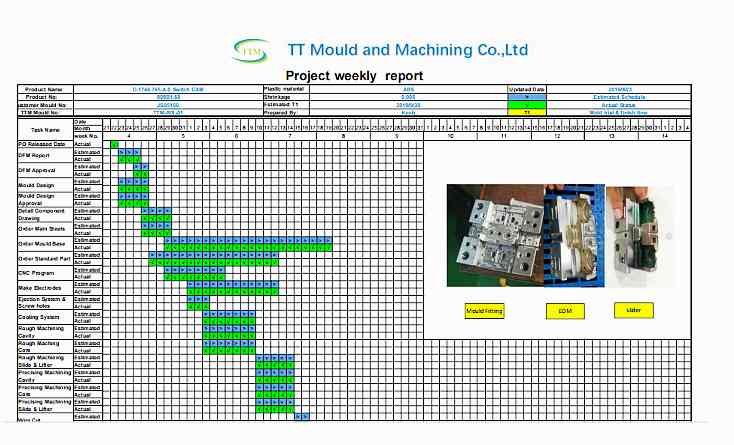

Weekly report to customer every Monday.

Mold or machining status with pictures or video on weekly report.

Mold trial report to customer.

Samples pictures with short shots, samples status and mold trial videos to customers.

Samples shipping to customers with FAI confirm.

Samples discussing and improving with customers until molds or samples approve.

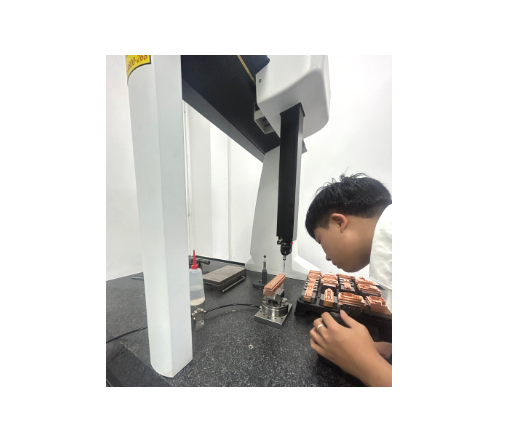

Mold steel certification and heatreatment report.

Mold hardness inspection.

Mold cores, inserts, eletrodos inspection.

Samples inspection with FAI for samples approve.

Mold checking list double check before mold shipping.

Normally shipping by air, by sea or by train.

TTM will make packing based on shipping methold.

Shipping by air 5~12 days for Europe and North America.

Shipping by train 30~45 days for Europe and North America.

Shipping by sea 45~60 days for Europe and North America.

———————————— Go hand in hand to shape the future with you ————————————

You and your team continue to make me pround picking TT Mould & Machining as a partner.

Blogs

How to solve parts short filling?

Plastic parts issues Design plastic Production plastic parts Customized plastic parts

Plastic parts deformation solution?

Defomation solution improving. Mold improving. Molded parts Good flatess parts

———————————— Don't hesitate to contact me anytime ————————————